Digital technology is entering the future pharmaceutical packaging with new smart packaging features offering opportunities and added value for patients, healthcare providers and pharmaceutical companies.

Nolato, in collaboration with ’smart technology specialist’ Water.io, presents standard packaging as well as complete bespoke solutions with built-in electronics to meet increased customer demands for patient centric design which will be at the heart of all future drug development.

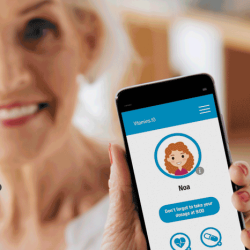

Increased compliance has become a big focus area due to rising healthcare costs resulting from therapeutic failure caused by non-prescription compliance. With smart digital caps the packaging can monitor the adherence and send reminders via an app to the patient or the caregiver based on the patient’s individual prescription. It can also stimulate daily use of, for instance, vitamins or food supplements by light signals from the cap and activate automatic replenishment of product subscriptions or encourage communication between the user and the brand owner.

Digital pharma packaging also provides numerous applications with regard to safety, with features such as user authentication, adult approval, time and dosage verification, and monitoring the handling instructions of a specific medicine. Yet another area of use is the collection of patient usage data during clinical trials, where digital packaging provides safe and simplified methods for capturing, registering, and monitoring information, which enables reduced lead times during the development of new drugs.

The application areas and the possibilities with smart technology pharmaceutical packaging are endless. Talk to us about your future packaging challenges. Nolato has the resources and the know-how to realize your ideas.

.jpg)

.jpg)